Understanding the Critical Role of SPD Monitoring

Surge protective devices (SPDs) serve as the first line of defense for valuable electrical equipment, making their optimal performance crucial for maintaining system integrity. The surge protective device lifespan directly impacts its ability to safeguard your infrastructure from damaging power surges and transient voltages. By understanding and actively monitoring key lifespan indicators, facility managers and electrical professionals can ensure continuous protection and avoid unexpected device failures.

Modern electrical systems face increasingly complex challenges, from renewable energy integration to smart grid technologies. These advancements, while beneficial, can introduce more opportunities for power quality issues that affect your surge protective device lifespan. Regular monitoring becomes even more critical as facilities rely heavily on sensitive electronic equipment that requires constant protection.

Essential Visual Indicators for SPD Health

LED Status Indicators and Their Meanings

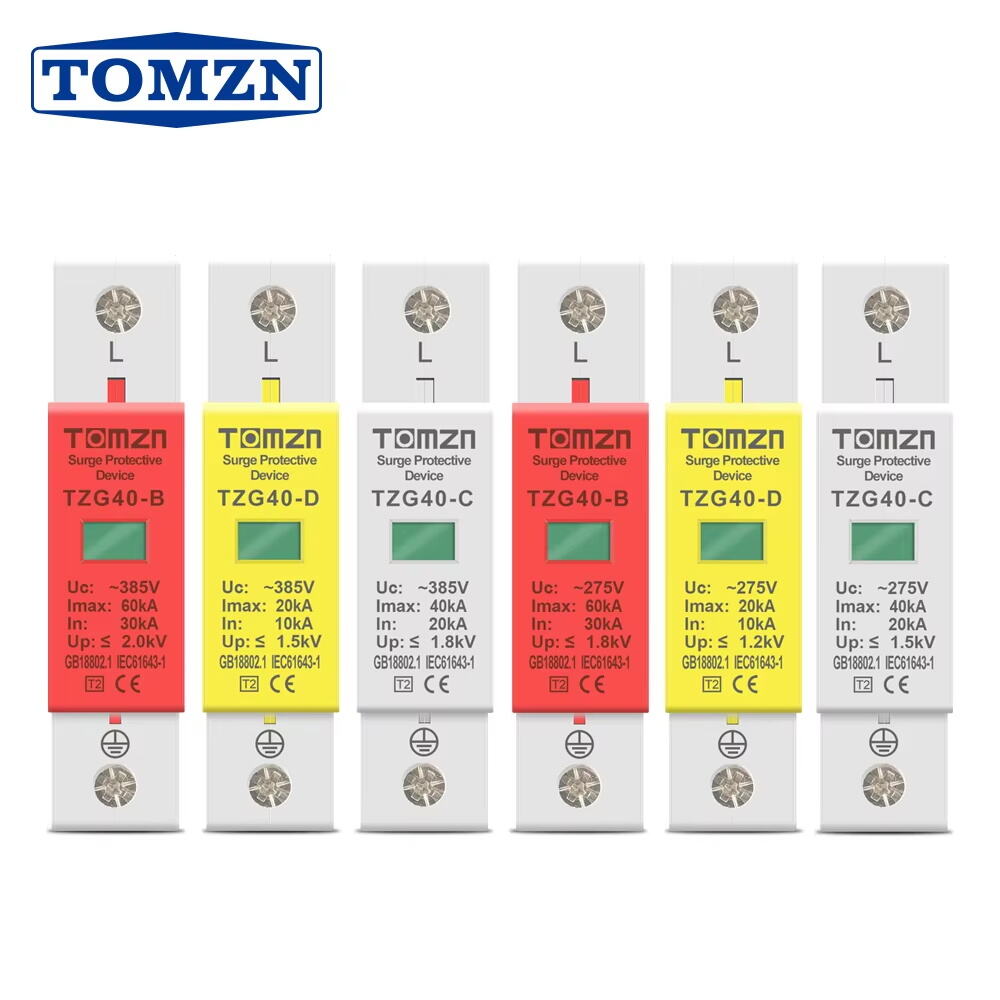

Visual monitoring systems, particularly LED indicators, provide immediate feedback about surge protective device lifespan status. Green LEDs typically indicate normal operation, while red or amber lights suggest compromised protection or end-of-life conditions. Modern SPDs often feature multiple LED indicators, each monitoring different protection modes or phases of three-phase systems.

Understanding these visual cues enables quick identification of potential issues. Some advanced units incorporate multi-color LED systems that display progressive wear levels, allowing maintenance teams to plan replacements before complete failure occurs. Regular visual inspections should become part of standard maintenance routines, with any changes in LED status prompting immediate investigation.

Physical Inspection Points

Beyond LED indicators, physical signs can reveal important information about surge protective device lifespan. Check for discoloration around connection points, which may indicate thermal stress or loose connections. Inspect the device housing for signs of damage, swelling, or thermal deformation that could compromise its protective capabilities.

Pay special attention to ventilation areas and ensure they remain clear of dust and debris. Proper airflow helps maintain optimal operating temperatures, directly affecting the device's longevity. Document any physical changes observed during inspections to track degradation patterns over time.

Advanced Monitoring Systems and Diagnostics

Remote Monitoring Capabilities

Modern surge protective devices often incorporate advanced monitoring features that enable remote surveillance of device health. These systems can track surge counts, protection status, and remaining surge protective device lifespan through network connections. Remote monitoring eliminates the need for frequent physical inspections while providing real-time alerts about protection status changes.

Building management systems can integrate with these monitoring capabilities, offering centralized oversight of multiple SPDs across facilities. This integration enables predictive maintenance strategies and helps optimize device replacement schedules based on actual usage patterns and environmental conditions.

Diagnostic Testing Methods

Professional diagnostic tools can provide detailed insights into surge protective device lifespan and performance metrics. These tests measure protection levels across different modes, verify proper grounding connections, and assess the overall health of protection components. Regular diagnostic testing helps identify degradation patterns before they lead to failure.

Some advanced SPDs include built-in diagnostic capabilities that perform periodic self-tests and report results through their monitoring interfaces. These automated diagnostics complement manual testing procedures and help maintain continuous protection awareness.

Environmental Factors Affecting SPD Longevity

Temperature and Humidity Considerations

Environmental conditions play a crucial role in determining surge protective device lifespan. High ambient temperatures accelerate component aging, while excessive humidity can lead to internal corrosion. Installing SPDs in well-ventilated areas and maintaining appropriate environmental controls helps extend their operational life.

Temperature monitoring systems near SPD installations can help identify potential issues before they affect device performance. Consider implementing additional cooling measures in high-temperature areas to maintain optimal operating conditions and maximize protection effectiveness.

Power Quality Environment

The quality of the power supply significantly impacts surge protective device lifespan. Frequent voltage fluctuations, harmonic distortion, and recurring surge events can accelerate wear on protection components. Regular power quality monitoring helps identify adverse conditions that might require additional protective measures.

Consider implementing power quality monitoring systems alongside SPD monitoring to gain a comprehensive understanding of the electrical environment. This data helps optimize protection strategies and predict maintenance needs more accurately.

Maintenance and Replacement Strategies

Preventive Maintenance Schedules

Implementing regular maintenance schedules helps maximize surge protective device lifespan through early problem detection. Develop comprehensive inspection protocols that include visual checks, diagnostic testing, and documentation of findings. Train maintenance personnel to recognize early warning signs of degradation and understand appropriate response procedures.

Create maintenance calendars that align with facility operations and critical equipment protection requirements. Consider seasonal variations in surge activity and adjust inspection frequencies accordingly to maintain optimal protection levels.

End-of-Life Planning

Developing clear end-of-life criteria and replacement strategies ensures continuous protection without unexpected gaps in coverage. Consider factors such as age, surge count history, and protection level measurements when determining replacement timing. Maintain an inventory of replacement units for critical applications to minimize protection downtime.

Document replacement procedures and maintain records of installed devices, including installation dates and service history. This documentation supports informed decision-making about replacement timing and helps optimize future protection strategies.

Frequently Asked Questions

How long does a typical surge protective device last?

The typical surge protective device lifespan ranges from 5 to 10 years, depending on installation environment, surge exposure, and maintenance practices. However, devices in harsh environments or those experiencing frequent surge events may require earlier replacement. Regular monitoring and maintenance can help maximize operational life.

What are the most reliable indicators of SPD end-of-life?

The most reliable indicators include LED status changes, increased frequency of surge events, failed diagnostic tests, and visual signs of damage or degradation. Remote monitoring systems can also provide advanced warning through trend analysis and performance metrics.

When should I replace my surge protective device?

Replace your SPD when monitoring indicates compromised protection, after significant surge events, when visual indicators show end-of-life status, or according to manufacturer recommendations. Additionally, consider replacement if the device has exceeded its expected service life or shows signs of physical damage.

How can I extend my surge protective device lifespan?

Extend your SPD's lifespan by maintaining proper installation conditions, conducting regular inspections, addressing power quality issues, and following manufacturer maintenance recommendations. Proper ventilation, temperature control, and prompt response to warning indicators also help maximize device longevity.